Modular Wastewater Treatment Plant

Containerized MBR systems are designed with simplicity, flexibility and durability in mind.

These containerized wastewater treatments plants provide high quality, portable treatment solutions ideal for remote and tight locations. The fully contained systems require minimal site preparation and are manufactured using rugged materials suitable for harsh environments. Once deployed, the systems are extremely low energy and low maintenance, with minimal operator supervision required. The inherently robust design is resistant to shock loading and reduced input conditions.

Advantages:

- Faster project completion time

- Requires very small foot prints which saves on land requirements

- Can be installed in more challenging project sites

- Requires much less civil and peripheral works

- Modular and expandable with zero downtime

- Utilizes most advanced technologies in water treatment

-

Low maintenance and operating costs -

No foul odor and noise

.jpg)

Scope Supply

| NO. | EQUIPMENT | SPECIFICATIONS | QTY | NOTE |

|---|---|---|---|---|

| 1 | Lifting Pump | H=13m, 380V | 1 | Underwater mobile |

| 2 | Suction Pump | H=10m, 380V | 1 | |

| 3 | Sludge return pumppump | H=4m, 380V | 1 | Underwater mobile |

| 4 | Dosage Pump (P Removal) | H=3.5bar, 220V, 22W | 1 | |

| 5 | UV disinfectant | Connection: Flange; DN50, Main pipe diameter: φ133, 220V, 240W | 1 | |

| 6 | Backwash Pump | H=10m, 380V, 400W | 1 | |

| 7 | Blower | H=3.5m, 380V, 4000W | 1 | |

| 8 | Mixer | 380V, 370W | 1 | |

| 9 | Fan | 220V, 100W | 1 | |

| 10 | Electric heater | L×W×H=600×95×300, 220V, 1500W | 1 | |

| 11 | Dosing tank (P removal) | Material: Glass fiber reinforced plastic, | 1 | |

| 12 | Backwash Tank | Material: Glass fiber reinforced plastic | 1 | |

| 13 | Microporous aerator | Air flowrate: 3Nm3/h/set | 1 | |

| 14 | Electric control cabinet | 1 | ||

| 15 | Pressure transmitter | Measurement Range: -99.9~99.9KPa, Output 4-20mA Signal, 24V Power supply, split type | 1 | |

| 16 | Plastic tube flowmeter | Measurement Range: 0.6~6m3/h, DN32, Socket connection | 1 | |

| 17 | Electromagnetic flowmeter | Measurement Range: 0~30m3/h, split type, Output 4-20mA Signal, DN50, 1.0MPa, Rubber lining, 316L Electrodes, 24V | 1 | |

| 18 | Float level gauge | 0~5m, Soft line | 5 | |

| 19 | Gas rotameter | DN40 PN0.6MPa, Measurement Range: 6~60m3/h, Flange connection, medium: air | 1 |

MBR Container System

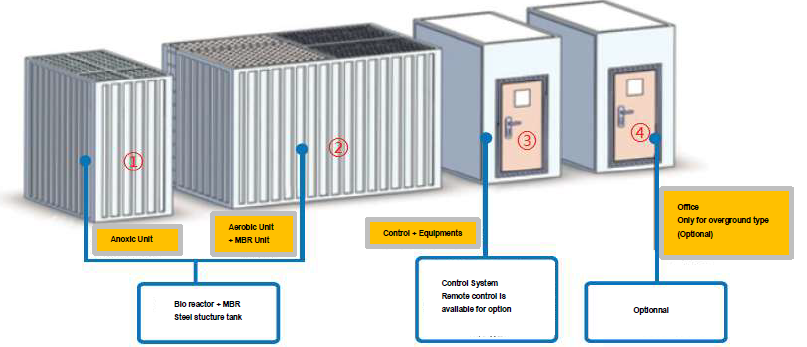

The integrated MBR plants adopts modular design, which is composed of four units, as shown in the figure below.

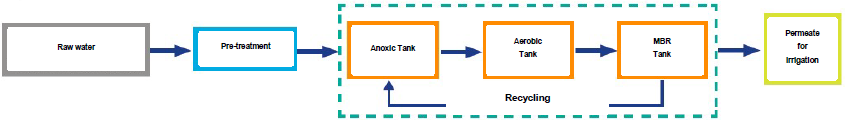

Process Route

The process flow of the system, which is mainly composed of pre-treatment unit and MBR integrated equipment. The core technology is the combination of a membrane module and a biochemical reactor.

The wastewater treatment system consists of aerobic tank, anoxic tank and membrane tank.

• Aerobic tank: the organic substants in the sewage will be degraded, absorbed and then decomposed by fully mixing with activated sludge composed of microorganisms. The aerobic bacteria take dissolved oxygen as electron acceptor and carbon source as electron donor for aerobic respiration in the aerobic tank, the final products are mainly carbon dioxide and water. Ammonia nitrogen will change into nitrate nitrogen under nitrite reaction through nitrite and nitric acid bacteria in the aerobic environment.

• Anoxic tank: nitrogen generated by nitrate nitrogen through denitrifying reaction under the action of denitrifying bacteria will be released into the atmosphere. In order to make full use of the carbon source, the Anoxic tank was placed before the aerobic tank, and the effluent of the aerobic tank flow returned to the Anoxic tank for denitrification.

• Membrane tank: hollow fiber membrane module will be installed in the tank, the water will be filtered by the micro pore on the surface of the membrane fiber. In order to prevent the foulling of sludge on

the menbrane surface, there is aeration device at the bottom of the membrane tank. The blower will provide the air to keep the membrane clean.

Scope Supply

| NO. | DESCRIPTION |

|---|---|

| 1 | Intake Pump |

| 2 | Coagulation unit |

| 3 | Pre-filtration |

| 4 | Micronic Filtering |

| 5 | High Pressure Pump |

| 6 | RO membranes |

| 7 | Re-mineralization column |

| 8 | Disinfection unit - Chlorine generator |

| 9 | Control board |

| 10 | Control accessories |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

| 11 | Trailer Mounted |

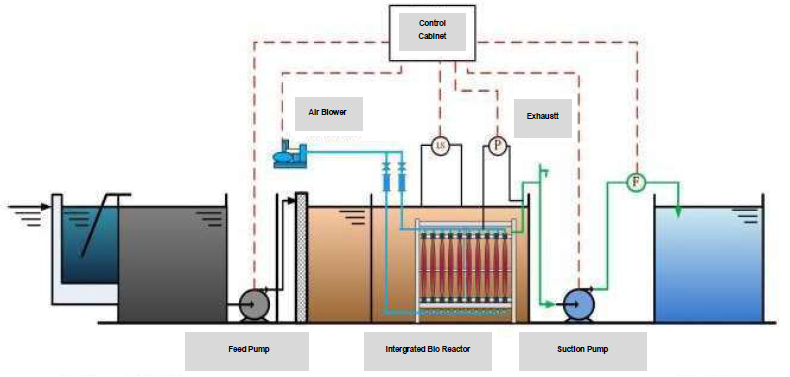

In addition, automatic operation and management can be realized through automatic control. The control system is composed of PLC control cabinet, suction pump, blower, air lift pump, solenoid valve, liquid level gauge and on-line monitoring instruments. According to the signal provided by the liquid level gauge, PLC controls the start and stop of suction pump, blower, return pump and solenoid valve

In addition, automatic operation and management can be realized through automatic control. The control system is composed of PLC control cabinet, suction pump, blower, air lift pump, solenoid valve, liquid level gauge and on-line monitoring instruments. According to the signal provided by the liquid level gauge, PLC controls the start and stop of suction pump, blower, return pump and solenoid valve

Characteristics

‣ Stable effluent water quality;

‣ Integrated equipment, small footprint, convenient transportation;

‣ Modular structure, quick installation;

‣ Low operating cost, wide application range