Dewatering Screw Press for Sludge Treatment

The Dewatering Screw Press represents the efficient and reliable management of sludge water, a secondary product across various sectors. This device is designed to exceed the capabilities of traditional sedimentation and dewatering methods, this equipment reflects our commitment to advancing environmental management technologies.

Product Description

The Dewatering Screw Press is a key piece of technology in modern wastewater treatment strategies, offering unparalleled efficiency in thickening sludge water up to 24% dry-matter content. Its design and functionality not only meet the needs of wastewater treatment plants but also cover the thickening of industrial water and wastewater within food processing operations. Integrating this press within new WWTP designs can significantly reduce construction costs by eliminating the need for large sedimentation tanks, offering a cost-effective and environmentally friendly solution.

Dewatering Process Description

Sludge water goes into the Dewatering Screw Press via a feeder pump, leading to an inlet chamber that optimizes the flow via an overflow system.

A critical step in the process involves the injection of a flocculant (polymer) into the sludge water, which helps solid particles clump together into “flocks”.

This flocculation process, taking place in the mixing chamber, is enhanced by slow agitation with the flocculant. Next, the sludge is moved to the screw assembly, which features fixed and variable helix plates that act as a self-cleaning filter.

This reliable design ensures a smooth dewatering process, finishing with a spring-loaded closure plate that maximizes dewatering efficiency by increasing the internal pressure.

Some Fields of Applications

• Municipal Waste Water Treatments

• Biogas Stations

• Slaughterhouses

• Oil Industry -> Oil, Gas & Mining industry

• Milk and Dairy Production

• Wine and Beverage Production

• Distillery Industry

• Food Processing

• Grease Trap

• Industrial waste processing

Key Benefits

✔ Energy Efficiency: Designed to operate with minimal energy consumption.

✔ Ease of Installation and Operation: User-friendly design ensures undemanding installation and operation.

✔ Durability: Surface treatment of critical parts guarantees resistance to wear.

✔ High Performance: Capable of efficiently thickening sludge from 0.5–5% at the inlet to 15–25% at the outlet, with specific sludges up to 45%.

✔ Low Noise and Vibration: Low RPMs ensure quiet and smooth operation.

✔ Versatility: Suitable for a broad range of applications across different industries.

✔ Automated Operation: Features an automated mode for operator-free operation.

✔ Cost-Effectiveness: Investment return could be as little as one year

✔ Technical and maintenance support

✔ Technical and maintenance support

✔ Modifiability & Accessories

✔ Technical development and enhancement

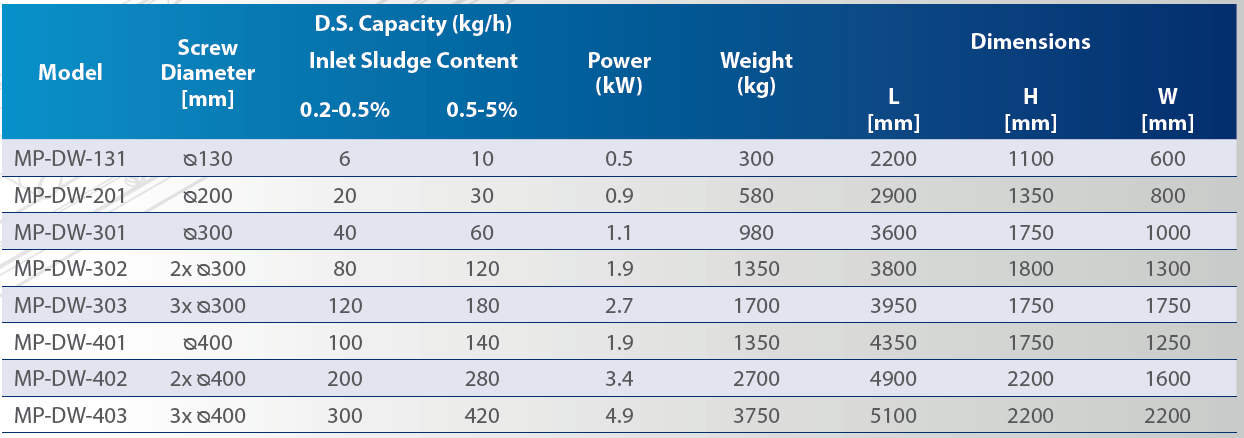

Parameters